How to properly clean lenses for UNKONEX laser cutting machine?

The focusing lens of the unikonex laser cutting machine is a precise optical component, and its cleanliness directly affects the processing performance and quality of the laser cutting.

Since the optical lens in the unikonex laser system is a consumable item, therefore timely cleaning of the lens is very necessary for extension the lens working life. In order to prolong the service life and reduce the user cost as much as possible, the lens must be cleaned in strict accordance with the following steps highly recommended by unikonex.

During the replacement process, the placement, inspection, and installation of the optical lens, must to protect the lens from damage and contamination. After a new lens is installed, it should be cleaned regularly according to unikonex operational manual.

Laser cutting machine lens cleaning procedure

When the laser cuts the textile or fabrics or other materials, the working surface releases a lot of gas and spatter, which will cause damage to the lens. When contaminants fall on the surface of the lens, energy is absorbed from the laser beam, resulting in a thermal lens effect. If the lens has not yet formed thermal stress, the operator can disassemble and clean it. During the installation and cleaning of the lens, any sticky matter or even finger print or marks on the lens will increase the absorption rate of the lens and reduce the service life. The following precautions must be taken:

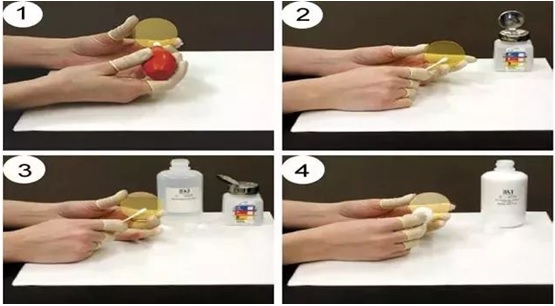

1. Take out the focusing mirror from the frame: Loosen the fastening screw and never use the bare finger to install the lens. Finger tips or rubber gloves should be applied.

2. Do not use sharp instruments to avoid scratching the surface of the lens.

3. When hold the lens, do not touch the special coating surface, just hold the edge of the lens.

4. Lenses should be placed in a dry, clean place for checking and cleaning. A good workbench should have several layers of cleaning paper towels on the surface and several cleaning lens tissues.

5. Users should avoid talking above the lens and keep food, beverages and other potential contaminants away from the work environment.

In the process of cleaning the lens, a low risk method should be adopted. The following operational precautions are established for this purpose and should be strictly followed by the user.

1. This step is necessary to blow off the float on the surface of the lens with a blower, especially a lens with tiny particles and floats on the surface. But don't use compressed air from workshop tubing , because it contains oil mist and water droplets, which will cause the pollution of the lens.

2. Cleaning the lens with a laboratory-grade acetone and laboratory-grade paper . Dip a proper amount of acetone or high-alcohol 95% alcohol and gently rotate it clockwise from the center of the lens to the edge. If necessary, both sides of the lens need to be cleaned. Carefully protect the lens when cleaning. If the lens has two coated surfaces, such as focus lenses, each surface needs to be cleaned in this way. The first side needs to be placed on a clean lens paper for protection.

3. If acetone does not remove all the dirt, then use acid vinegar to clean. When the vinegar is cleaned, it is used to dissolve the dirt to remove the dirt, but it will not cause damage to the optical lens. This acid vinegar can be experimental grade (diluted to 50%), or white vinegar containing 6% acetic acid. The cleaning procedure is the same as for acetone cleaning, then the acid vinegar and the dry lens are removed with acetone. At this time, the cotton are frequently changed to completely absorb the acid and hydrate, Until it is clean.

4. When contaminants make the lens damaged, cannot be removed by cleaning, especially due to metal splashes and dirt damage the coating surface, user has to replace the lens without any other choice.

5. Install the lens barrel and the nozzle, adjust the focal length, tighten the fastening screw, and keep the convex surface facing down when the focusing lens is installed.

It can be seen that in order to achieve a better cutting quality, the requirements for lens cleaning is must! Moreover, since the air contains moisture and oil, the long-term combination with the dust in the air will cause lens contamination, and the cutting beam is unstable, so that the cutting effect and quality are not right to standard. Therefore, the laser cutting machine lens must be cleaned in strict accordance with the above method to extend the lens life.