Cutting workers, as an integral part of industries such as manufacturing and construction, have always been a focal point regarding wage levels, work intensity, and career development prospects. However, with the relentless advancement of technology, particularly the widespread adoption of laser cutting machines, traditional manual cutting is facing unprecedented challenges. This article delves into the reasons why laser cutting machines are poised to replace traditional manual cutting, based on the current situation of cutting workers.

I. Current Wage Situation of Cutting Workers**

The wage levels of cutting workers vary depending on factors such as region, enterprise size, work experience, and skill level. According to data from Chinese job websites, the monthly salaries of most cutting workers in China currently hover at a moderate level, with the national average monthly salary being approximately ¥5,440 (equivalent to $780 USD). Economic development levels, living costs, as well as the size and nature of enterprises in different regions all influence the wages of cutting workers. For instance, cutting workers in first-tier cities tend to have relatively higher wages, while large enterprises and foreign-funded enterprises often offer higher salaries, which can reach up to ¥8,000 (equivalent to $1,142 USD).

II. Work Intensity of Cutting Workers**

The work intensity of cutting workers is notably high, primarily reflected in long working hours, repetitive labor, specific body positions and exertions, as well as working environments and conditions. Continuous work for extended periods, cutting in the same position, and unfavorable factors such as noise and dust in the working environment may all lead to physical fatigue, strain, and even the occurrence of occupational diseases. While the development of modern technology has alleviated the labor intensity of workers to some extent, the high-intensity nature of cutting work remains a significant issue.

III. Career Development Prospects of Cutting Workers**

The career development prospects of cutting workers are influenced by various factors, including industry development trends, technological progress, market demand, as well as personal skills and experience. While the transformation and upgrading of the manufacturing industry and the emergence of new industries have provided new employment opportunities for cutting workers, the development of automation and intelligent technologies has also impacted traditional cutting workers. Workers who master new technologies and skills will be more competitive, and experienced cutting workers can also adapt to the demands of industry development through skill upgrading and experience accumulation.

IV. Advantages of Laser Cutting Machines and the Possibility of Replacing Traditional Manual Cutting**

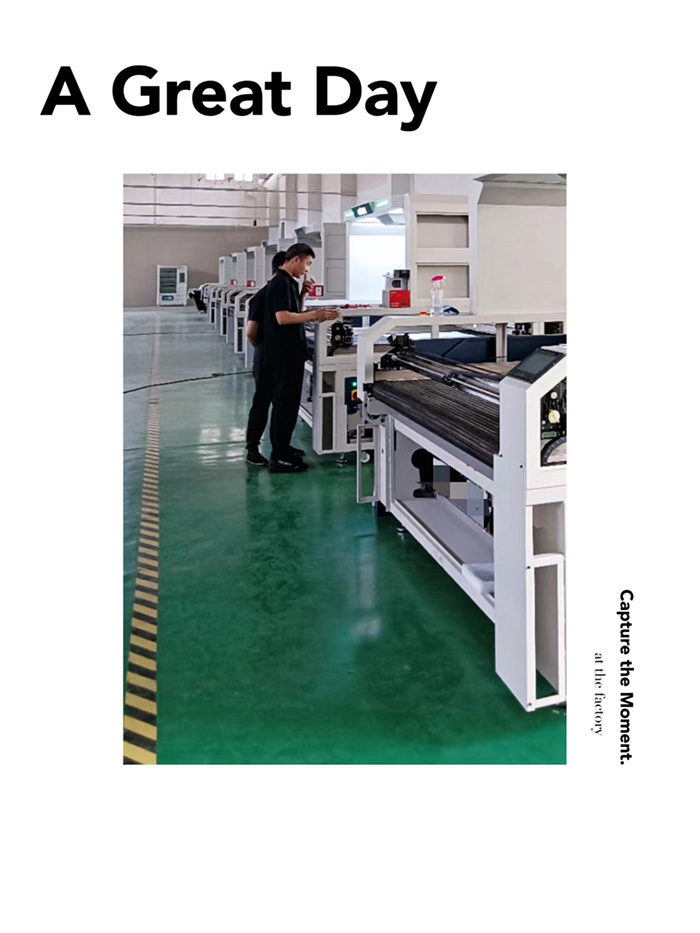

As advanced cutting equipment, laser cutting machines offer significant advantages such as high precision, high efficiency, and a high degree of automation. Compared with traditional manual cutting, laser cutting machines can greatly enhance production efficiency and cutting precision, reducing errors and waste caused by human factors. Additionally, laser cutting machines can adapt to the cutting needs of various complex shapes and materials, providing robust support for customized products.

With the transformation and upgrading of the manufacturing industry and the advancement of intelligent development, more and more enterprises are adopting automated equipment such as laser cutting machines to improve production efficiency and quality. This trend not only reduces the demand for traditional cutting workers but also provides more opportunities for workers who master new technologies and skills. Therefore, in the long run, laser cutting machines are expected to gradually replace traditional manual cutting and become the mainstream cutting method in manufacturing and other fields.

V. Conclusion**

In conclusion, laser cutting machines are gradually favored by industries such as manufacturing due to their advantages of high precision, high efficiency, and a high degree of automation. Compared with traditional manual cutting, laser cutting machines can not only improve production efficiency and cutting precision but also adapt to complex needs such as customized products. Therefore, in the long run, laser cutting machines are expected to gradually replace traditional manual cutting and become the mainstream cutting method. This trend not only requires cutting workers to continuously learn and master new technologies to adapt to the demands of industry development but also presents new opportunities for their transformation and development.